Main questions below in BOLDFACE. Any advice is greatly appreciated!

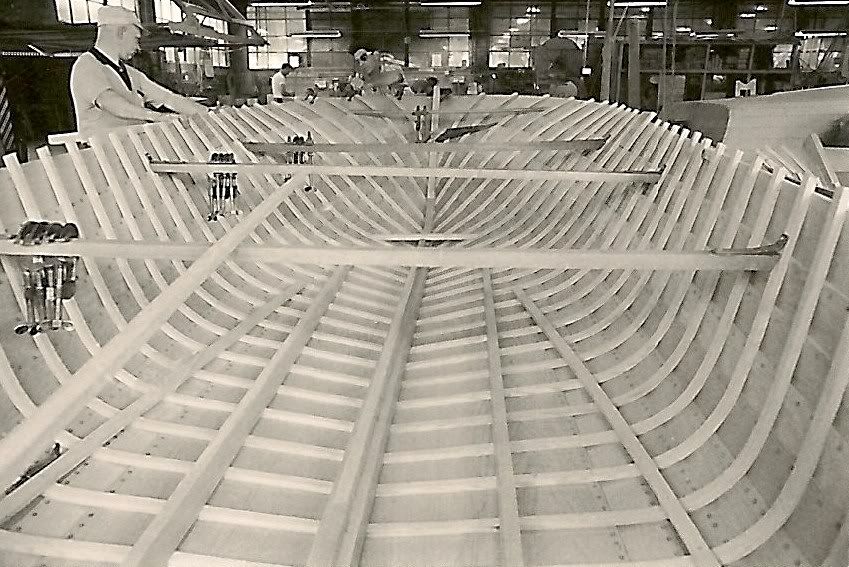

Here it goes: I've stripped the interior out of my boat, and I've done a pretty complete survey of the frames and planking. Ouch. I'm basically going to be building a new boat. I knew there were a few (4-6?) broken or seriously rotten frames when I acquired the boat. I also had assumed I'd find a fair number more frames with rotten tails under the keelson, etc. Here's a diagram of what I really found:

With frames on 6" centers, I just laid a tape measure in the bottom and numbered the frames by the distance in feet from the transom. The transom itself is "0". The label for the keel is really the keel, keelson, & stem combined as a unit. The other vertical lines are the floor supports/risers.

I have two main concerns with the bottom shape. First, the keel is bowed upwards a bit in the middle. Since I'll probably replace the entire keel anyway, that will be corrected. Second, I'm concerned about the lateral shape of the bottom. Since so many frames have had a patch inserted (note: not scarfed into the whole, just a piece replaced & butt-joined), I'm 99% sure the boat has had its sides sag down. This is especially noticeable in the starboard stern quarter where so many frames are cracked at the turn of the bilge and rotten from there to the keel.

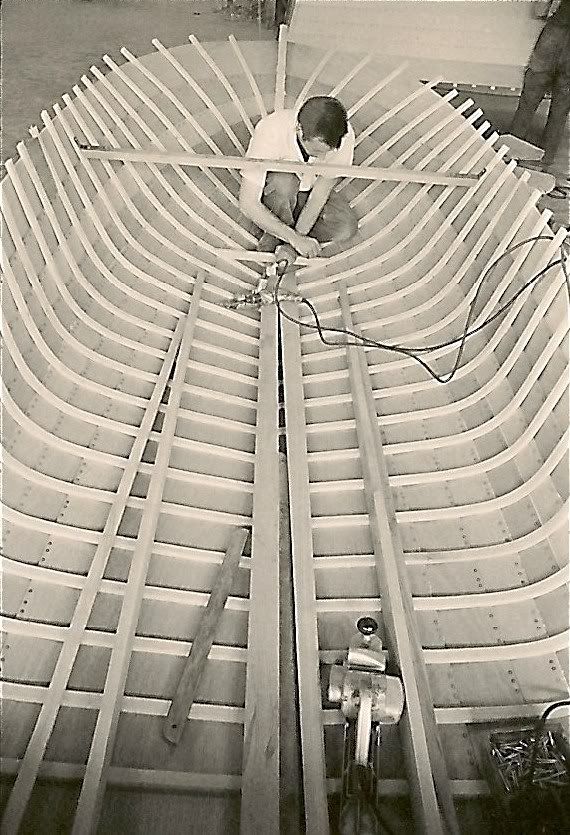

See that hump at the outer edge of the garboard plank near the transom? Facing forward, it's a bit tougher to capture on camera, but look at this:

All the frames through the midsection seem to be crowned... concave on the bottom, laterally, between the floor risers (outermost longitudinal member) and the keel. On the transom, there is a straight line from the turn of the bilge to the keel. Should it be any different as you move forward, or should that continue to be a straight line, albeit possibly with a changing slope/deadrise?

As much as I love having gotten an almost new trailer with the boat, I think it might be partially to blame. The bunks do not sit under the stringers/AKA sister keelsons, but rather to the outside of them, just below the joint between the garboard and the first narrow plank. Here's my assessment of what that's doing:

As discussed under the other topic, the flooring isn't necessarily supposed to be flat laterally on a Peshtigo model, but look back at that photo with the level in it... the floor riser is a good 1.5" below the plane formed by the sister keelsons. Isn't that excessive? It also seems to be lower on the starboard side than on port. I've lightened up the boat enough that I can lift the transom slightly, and it appears that some of this crowned effect goes away when the boat is not resting fully on the trailer.

I just want to make sure that I restore the boat's intended shape while I'm restoring the structure. Otherwise, I'm going to have a boat that's structurally sound, but a poor (or unsafe) performer. I guess it comes down to these facts and the following conclusion: Since the transom has a straight line from the turn of the bilge to the keel, and since a planing hull is supposed to be straight longitudinally in the rear portion (say, ~5' here), I'm guessing that the frames should be straight (laterally) between the bend and the keel, and also at a constant deadrise angle. Is that right? Does that make sense? I'm just putting that two + two together as I write....

Finally, if the trailer is at least partially at fault, it should be a simple matter to unbolt and reposition the bunks to lie directly under the sister keelsons. I may want a second set of guides/bunks farther out if I do that, just so the boat won't be tippy when sitting on the trailer.

Again, any and all thoughts & advice are greatly appreciated. I'm trying to move forward on this as quickly as possible!

-wte