Outer keel and stem replacement

Moderators: a j r, TDockside, Miles, Moderators

Outer keel and stem replacement

Hello everyone,

I've just begun restoration of a 64 16' Peshtigo built Thompson-not sure of the model-Sea Coaster perhaps. I've begun by first removing the outer keel, which is made up of 3 pieces- 1 long piece from stern forward to just in between thru keel bolts, then 2 short pieces, followed by stem. Should it be 2 pieces-outer keel then stem- or 1 all the way thru? Thanks for the help and I'm very glad to be onboard!

All the best,

Jason

I've just begun restoration of a 64 16' Peshtigo built Thompson-not sure of the model-Sea Coaster perhaps. I've begun by first removing the outer keel, which is made up of 3 pieces- 1 long piece from stern forward to just in between thru keel bolts, then 2 short pieces, followed by stem. Should it be 2 pieces-outer keel then stem- or 1 all the way thru? Thanks for the help and I'm very glad to be onboard!

All the best,

Jason

-

Phill Blank

- Posts: 412

- Joined: Thu Jan 05, 2006 4:20 pm

- Location: Hurley, Wisconsin

Re: Outer keel and stem replacement

Jason,

It should be two pieces, the main keel and the stem. The keel and stem joint is generally where the thru bolts are and they over lap with a scarf type joint.

Good Luck,

Phill

It should be two pieces, the main keel and the stem. The keel and stem joint is generally where the thru bolts are and they over lap with a scarf type joint.

Good Luck,

Phill

Re: Outer keel and stem replacement

Thanks Phill! I assume the stem will have to be steamed as well. Will the outer keel make the small bend at the forward end? Just trying to prepare and be ready when I finally source suitable white oak. This is my first restoration and I want to get it right. Also, I read a write up by Andreas about this procedure and he mentioned plugging the screw holes. My boat is still on the trailer with very little working room, but it appears there is a very small gap between the garboard planks. Should I pry the planks out to find those holes or is it possible to feel around in there and somehow drill them out for a plug? Any particular size?

Hopefully this winter weather will clear up soon and allow me to get back to work on it

Jason

Hopefully this winter weather will clear up soon and allow me to get back to work on it

Jason

-

Phill Blank

- Posts: 412

- Joined: Thu Jan 05, 2006 4:20 pm

- Location: Hurley, Wisconsin

Re: Outer keel and stem replacement

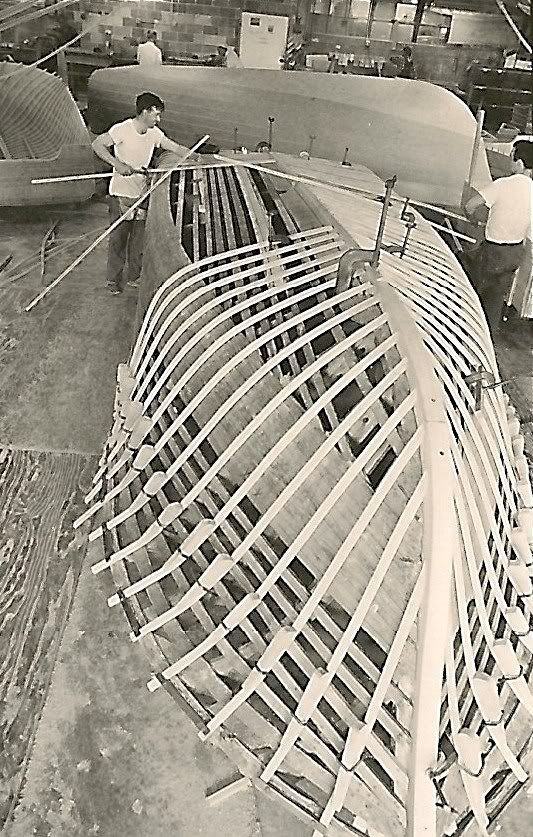

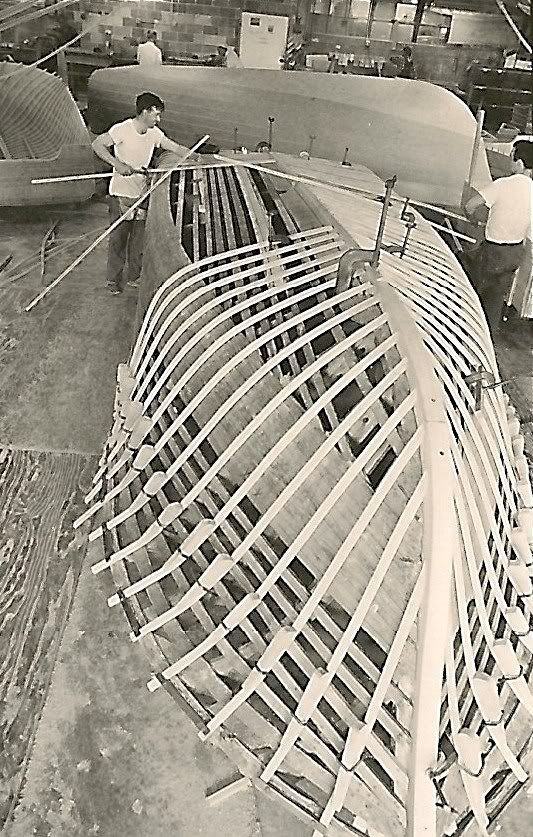

Here is a photo of a hull being built which should give you some idea of what was originally done.

I hope this is of help.

The screws and bolts on the keel should be countersunk and plugged. The flat head screws and small machine screws that hold the planking together and to the frames will be slightly recessed and filled with filler. Once you strip the paint you should see these. There should be no gaps between the garboards or planking.

Good Luck,

Phill

I hope this is of help.

The screws and bolts on the keel should be countersunk and plugged. The flat head screws and small machine screws that hold the planking together and to the frames will be slightly recessed and filled with filler. Once you strip the paint you should see these. There should be no gaps between the garboards or planking.

Good Luck,

Phill

Re: Outer keel and stem replacement

Jason,

Could you post some photos of what things look like now. I will need to make the same repair to my Sea Coaster and I'd like to see what to expect before I take it apart.

Verne

Could you post some photos of what things look like now. I will need to make the same repair to my Sea Coaster and I'd like to see what to expect before I take it apart.

Verne

Re: Outer keel and stem replacement

The photo does help- I see they are installing the ribs and I see the holes for the outer keel bolts at the foot.

Andreas mentioned plugging the old screw holes in the bottom of the boat. I assume that's meant to be the screw holes in the keelson from the original outer keel screws. I would like to somehow drill and plug those holes without prying back the garboard planks, as they are in perfect shape as is.

I'll have to see if it's possible once it dries up a bit here. It's a cold muddy mess here in Louisiana currently!

Verne, most of the outer keel is off now. When I next get under there I'll snap some pics and as I go along.

Jason

Andreas mentioned plugging the old screw holes in the bottom of the boat. I assume that's meant to be the screw holes in the keelson from the original outer keel screws. I would like to somehow drill and plug those holes without prying back the garboard planks, as they are in perfect shape as is.

I'll have to see if it's possible once it dries up a bit here. It's a cold muddy mess here in Louisiana currently!

Verne, most of the outer keel is off now. When I next get under there I'll snap some pics and as I go along.

Jason

Re: Outer keel and stem replacement

Welcome aboard Jason.

Just drill out those screw holes a bit larger than current and slam a wood plug in there with some adhesive on it. When the glue dries, trim it flush with the surface. No need to pry back the garboard planking. Just drill thru them.

I'll take a cold muddy mess over this frozen tundra. Actually, it's warming up. It's +21 right now in Minnesota. NO snow tho

Andreas

Just drill out those screw holes a bit larger than current and slam a wood plug in there with some adhesive on it. When the glue dries, trim it flush with the surface. No need to pry back the garboard planking. Just drill thru them.

I'll take a cold muddy mess over this frozen tundra. Actually, it's warming up. It's +21 right now in Minnesota. NO snow tho

Andreas

Re: Outer keel and stem replacement

Thanks Andreas! Hopefully spring is just around the corner for us all.

I gotta get this boat done and stop complaining. I don't want to to be stuck on shore after the thaw watching the boats go by!

Jason

I gotta get this boat done and stop complaining. I don't want to to be stuck on shore after the thaw watching the boats go by!

Jason

Re: Outer keel and stem replacement

Verne, I've had to put off the outer keel replacement due to being unsuccessful at finding any quarter sawn white oak in North Louisiana or surrounding areas. I've instead decided to first tackle sanding the inner hull as well as window frame repairs and getting new floor panels cut and ready for install.

I'm heading to North Dakota in a couple of weeks, so hopefully I'll have better luck finding suitable white oak in more northern climes.

Jason

I'm heading to North Dakota in a couple of weeks, so hopefully I'll have better luck finding suitable white oak in more northern climes.

Jason

Re: Outer keel and stem replacement

Jason. Can you or anyone explain why you must find quarter sawn for the outer keel? I would think most any white oak in correct thickness would be more than suitable (treated with CPES). Finding white oak in length and thickness is difficult enough let alone quarter sawn.

-

Phill Blank

- Posts: 412

- Joined: Thu Jan 05, 2006 4:20 pm

- Location: Hurley, Wisconsin

Re: Outer keel and stem replacement

Jason,

Quarter saw white oak can be found by looking thru lumber of the correct thickness you are looking for by going thru a stack of lumber to find boards with growth rings that are perpendicular to the width of the board.

Also a board that has growth rings parallel to the width can be cut into strips which will have the growth rings perpendicular to the width of the strip which will be quarter sawn lumber.

Quarter sawn lumber is more stable then other cuts of lumber and is stronger when being bent.

You can also glue up a couple boards that are thinner to get the thickness you want. Use phenolic glue when laminating.

I hope this of some help.

Good Luck.

Phill

Quarter saw white oak can be found by looking thru lumber of the correct thickness you are looking for by going thru a stack of lumber to find boards with growth rings that are perpendicular to the width of the board.

Also a board that has growth rings parallel to the width can be cut into strips which will have the growth rings perpendicular to the width of the strip which will be quarter sawn lumber.

Quarter sawn lumber is more stable then other cuts of lumber and is stronger when being bent.

You can also glue up a couple boards that are thinner to get the thickness you want. Use phenolic glue when laminating.

I hope this of some help.

Good Luck.

Phill

Re: Outer keel and stem replacement

You do NOT need quarter sawn lumber for the keel and keelson. Flat sawn or rift sawn is fine.

Anderas

Anderas

Re: Outer keel and stem replacement

I've located white oak, but only in 8' lengths and kiln dried. My idea is to have two scarf joints for the stem and outer keel. Is scarf direction important? Also, should I soak the lumber after cutting to shape due to it being kiln dried?

This my first bending attempt and I don't know the best approach. Could I epoxy the scarfs, screw down the outer stem till it approaches the foot, use a steam bag at and forward of the foot for the stem and after steaming for an hour bend it in place still in the bag, screw it down temporarily, let it cool, remove the bag and fasten?

Thanks for any advice you give.

Jason

This my first bending attempt and I don't know the best approach. Could I epoxy the scarfs, screw down the outer stem till it approaches the foot, use a steam bag at and forward of the foot for the stem and after steaming for an hour bend it in place still in the bag, screw it down temporarily, let it cool, remove the bag and fasten?

Thanks for any advice you give.

Jason

Re: Outer keel and stem replacement

If you have a good scarf, direction is not important. Epoxy is not a good choice for white oak. If you use epoxy, read about it and methods necessary with white oak.

Kiln dried is fine for the outer keel, since it's straight. You will have to soak the materials you will steam bend for the curved stem. Soak it for several weeks.

Andreas

Kiln dried is fine for the outer keel, since it's straight. You will have to soak the materials you will steam bend for the curved stem. Soak it for several weeks.

Andreas

Re: Outer keel and stem replacement

Got it. Thanks Andreas!

Jason

Jason