Rull of thumb for steaming is one hour per inch of thickness.

When I bent my ribs which were approx. a half inch thick I steamed then for 30 Minutes.

Not knowing how much experience you have with this I will offer some unsolicited thoughts from my steaming experience.

1.DO NOT totaly block off the end of your steam tube. You want the steam to flow thru. Think of steam

coming out of the spout on a water kettle. I use a shop towel that is loosely stuck in the steam box end.

If the steam doesn't flow thru the tube you will not achieve the desired results.

2. Drill a small hole in the side of your tube and put in a cheap kitchen thermometer. You will want 212 dgrees F as that is the boiling point of water.

I would puy it towards the open end of the tube. Seal the hole with a little RV type casket coumpond.

3. Don't be suprized if the PVC tube gets soft. The steam will do that.

4. Have a good pair of heavy gloves on to handle the steamed wood with. It will be hot.

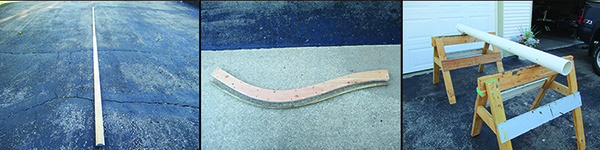

The pics shows my steamer going at a full boil. The shop towel is laying on top. The thermometer is on the backside of the box about where the towel is. I blocked about half the opening with the towel.

- IMG_0106.JPG (56.15 KiB) Viewed 51823 times

Hope this helps and good luck. Let us know how it turns out.

Torchie.